Compaction

Soil and sand, Gravel and stone fill

Plate compactors are best suited for compacting granular materials. Granular soils can be included in this, however cohesive soils such as silt and clay are best compacted by a vibrating rammer. Get reversible plate and anti-vibration handle. About 25 m2 per day. (2 days for basecourse, 2 days for sand)

Imposed loads varies from approximately 1.5 kN/m2 (153 kg/ m2) in domestic buildings to approximately 10 kN/ m2 (1053 kg/ m2) in heavy industrial areas. 4.74 kN/ m2 (500 kg/ m2 is typical for office, storage space and similar.

USA standard for garages is 50psf (2.39 kN/ m2)

Main road roller – 40Kn, Plate compactor – 16Kn chevpac.co.nz/catalogue/page/plate-compactors_CCT_S35/plate-compactor-c-100b-petrol 3-4 passes required

Meiwa 60Kg Honda GX120 3.5hp Engine, Weight 68kg., Plate Size 525 x 350mm., Travelling Speed 24-27 m/min., Vibration Frequency 90.0Hz (5400vpm), Centrifugal Force 10.8Kn (1100kgf). 14 hours Fuel consumption: 1.4 l/h

Wacker Neuson – MP15 $1750 Operating weight: 88 kg, Centrifugal force: 15 kN, Base plate size (w × l): 500 × 588 mm, Engine performance (max.): 4.2 kW (5.5HP), Fuel consumption: 1.5 L/h, Advance travel max. (depending on soil): 20 m/min powerpac.co.nz/_products//Machinery/CompactionEquipment/AsphaltPlates/WackerNeuson-MP15-88KgPlate

trademe.co.nz/a/marketplace/building-renovation/tools/power-tools/compactors/listing/3613030686

Nib Wall

Poured concrete establishes about half of its final strength after about one week of curing. Curing is defined as a chemical process the concrete goes through in the days immediately after it is poured. While full strength does not occur for 28 to 60 days, depending on conditions, the building process can begin when the foundations are about 50 percent cured.

The minimum foundation depth for buildings within the scope of NZS3604:2011 is 200mm minimum below cleared ground level. To reduce the risk of excessive foundation movements, the foundation depth for residential buildings in should generally be a minimum of 450mm below the adjacent cleared ground level and into good ground.

Nib wall is to retain and protect the roadbase. Walls are supported by the vertical steel structural members on the pier footings.

Options:

- Firth blocks – half wide – Plastered or schist veneer over

- 200x50mm landscape timber

- Cement sheet over steel C section

- Brick

- Tile

- Cedar cladding

- Sheet steel/Stainless

- Rubber.

Other cladding – above soil 225mm.

The cleared ground alongside must slope away from the building’s walls at a rate of not less than 1 in 25 for a distance of at least 1 m

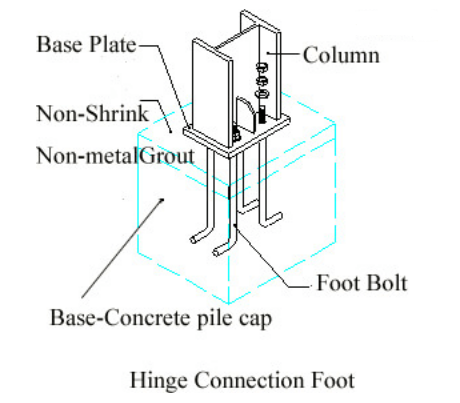

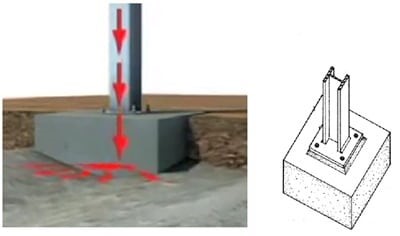

Pier Footings for Vertical Structural Members

Typically a pile for a cast in bracket would have a 450mm diameter hole 2.0m deep usually with a 550mm square cap,

Based on load: 450mm square by 450mm deep should suffice.