0.31 R-value requirement

Rebating improves the thermal performance, but adds unnecessary complexity and cost.

Avoid aluminium and stainless steel (Outdated)

Both argon and krypton achieve optimal insulating performance in spacer sizes less than the standard 1/2 inch, making it a compromise as the optimum spacer size is 12-18mm for air. A reduced air gap performance but an increased performance because of the noble gas.

In highly insulated houses, even with warm edge spacers, there will be condensation at the bottom edge of the pane with double glazing. This is because of convection causing colder argon adjacent to the outer pane sinking to the bottom of the unit (In poorly insulated buildings condensation will be at other points). Triple glazing eliminates this problem because of the two cavities.

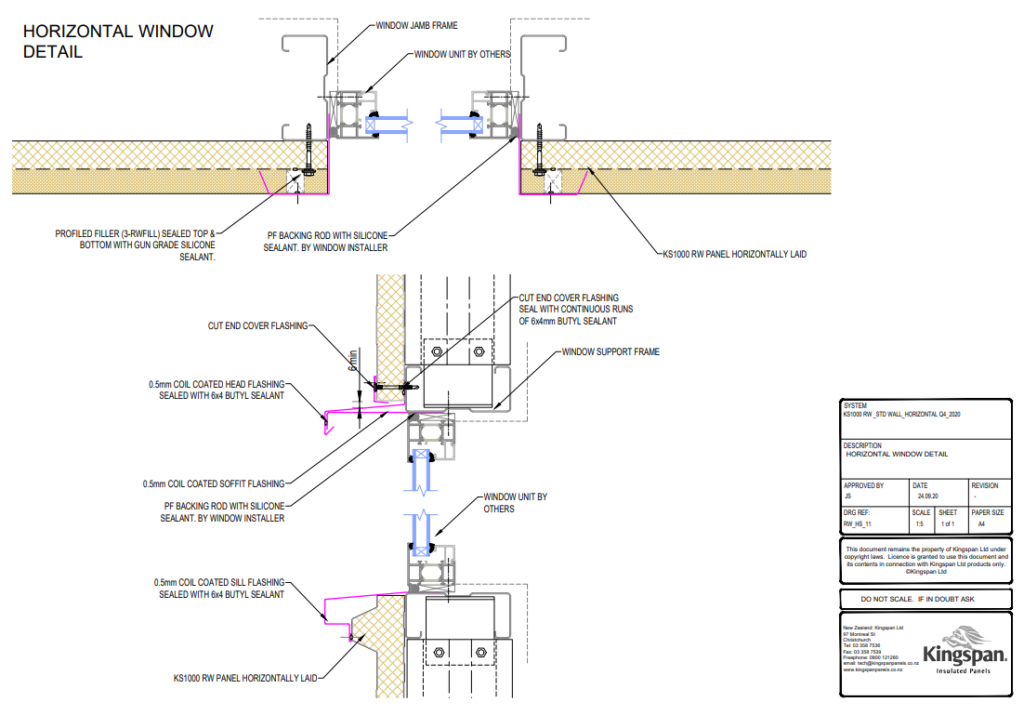

Gaps between the frame and the wall should be sealed with low expanding foam backed-up with a single-sided, pre-folded high-performance adhesive tape (Pro Clima or similar) to provide an airtight bond between the window frame and the wall / vapour control layer.

The curing time for the silicone is 3mm per day, assuming fair weather conditions. This normally comes out at approximately 1-2 weeks.

You may also hear the term drying time being used – this refers to the initial evaporation of moisture, which leaves the silicone dry to the touch, rather than the longer curing process.

Thermally efficient (“warm edge”) spacers separating the panes of glass. Structural foam with, typically, a polysulphide seal. This technology is often referred to as ‘warm edge’.

Edgetech Triseal NO Metal Rated for Arctic conditions (Cheap ones are as low as 2 m K/W)

Edgetech Super Spacer Warm Edge Spacer Bars 40-year performance guarantee. 6.5 m K/W (Best). Thermal Conductivity 0.15 R1.13. Flexible spacer made of silicone foam with integrated desiccant and side adhesive. For panes, the longest side is less than or equal to 1.5 m, a 5 mm height of secondary seal has to be used for determining the thermal bridge coefficient of the glass edge, for larger elements 7 mm. Only valid with Hotmelt Butyl secondary seal. Glasscorp NZ (Supplier)

Quanex – Super Spacer® T-Spacer™

- Two-sided acrylic adhesive allows immediate handling of the units

- Passive House phA certificate for Arctic climate

- Super Spacer® TriSealTM/T-SpacerTM Premium Plus from structural foam processed in triple-pane insulating glass

There are two types of Low-E coatings: hard and soft. The difference between them is their method of application, their transmittance and their durability.

- Hard (e.g. Pilkington K glass): applied during the manufacturing process. Emissivity between 0.15 and 2.0

- Soft (e.g. St Gobain Planitherm Total) : applied after manufacture. Emissivity between 0.05 and 0.10. They produce a lower u value. Soft coatings tend to degrade when exposed to air and moisture, are easily damaged, and have a limited shelf life.

Flexible (“Warm edge”) spacers have been developed using pliable, flexible thermoplastic or silicone-based materials with incorporated molecular sieves. Among these, the hot melt butyl type spacers with no additives are the best.

TPS® – advanced solution for insulating glass spacers

12-14mm is optimum gap. Thicker glass makes little difference

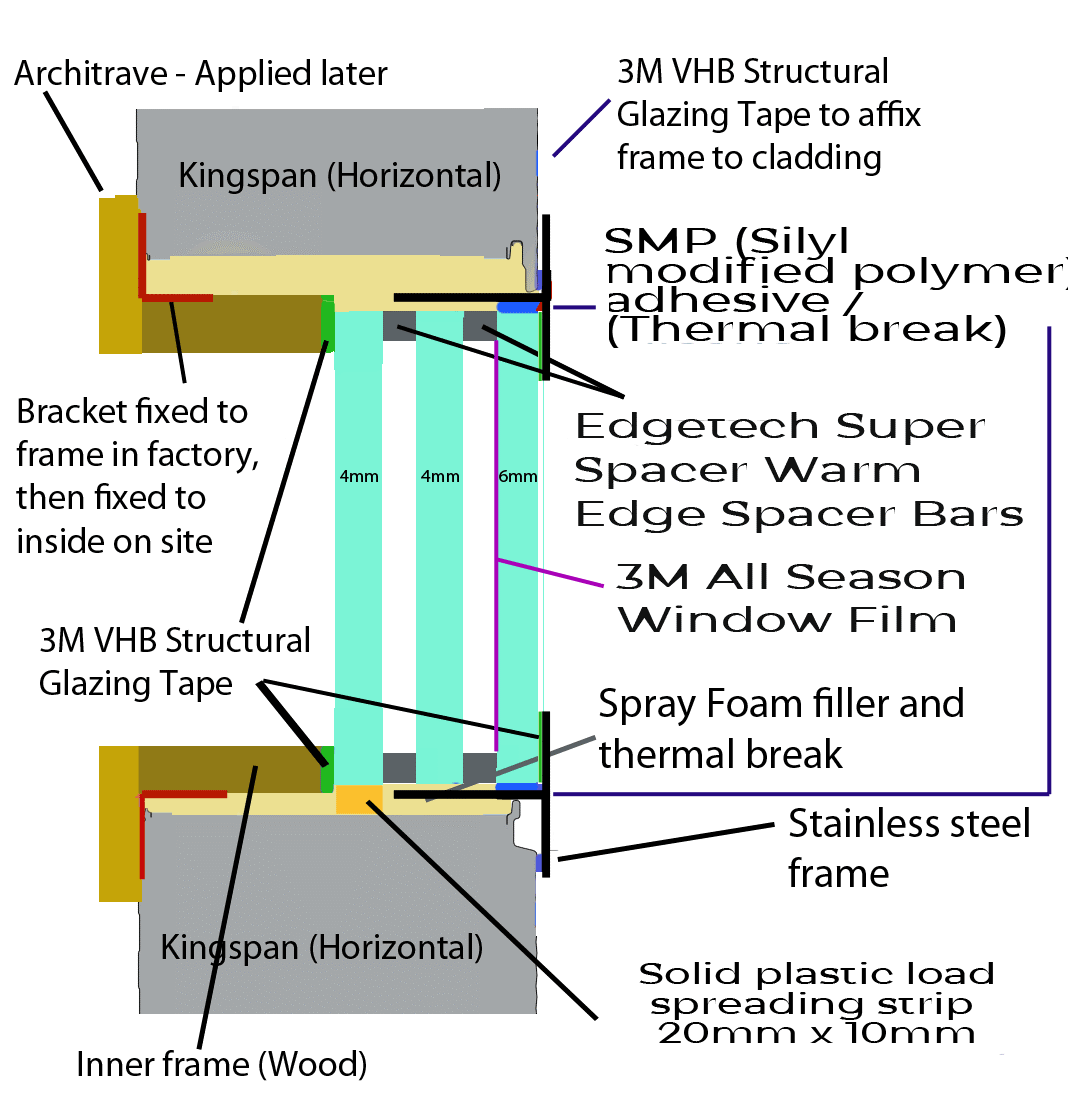

3M All Season Window Film R0.44

Double glazed (including warm edge spacer, thermal break) = R0.8

Double glazed (including warm edge spacer, thermal break, 3M film) = R1.24

Triple glazed (including warm edge spacer, thermal break) = R1.25

Triple glazed (including warm edge spacer, thermal break, 3M film) = R1.69

Triple glazed (including warm edge spacer, thermal break, 3M film both sides) = R2.13 (Centre of pane)

Edge of pane R3.21

Secondary glazing adds R0.19

Curtains add R0.26

Low E adds R0.16

Argon adds R0.17

Internal shutters add R2.97 for 95mm Expol Platinum (60mm + 35mm plus 2x 3mm mdf) (36mm total thickness for triple glazing and 3M) Total = R1.69 + R2.97 = R4.66

Float glass 4mm R0.17 $45 m2

Double glazing about $200 m2 in NZ

Lexan 4.5mm R0.19 $100 m2 U values:

For example, a 12mm space provides 36% better thermal performance than an 6mm space (for argon-filled SuperTherm™ double glazing). The space should be at least 10mm and not more than 18mm.

We supply glass cut to size from our factory to competent DIYers alliedglass.co.nz/auckland-glass-supply

Double glazing, and secondary glazing (with a suspended film created that creates an air gap between the film and the glass) can reduce heat loss by 60% and can reduce condensation. genless.govt.nz/assets/Individuals-Resources/low-emissivity-film-thermal-impacts-report-2015.pdf

The anti-long wavelength IR reflective coatings (the low e coating) are one way, in effect. They are applied to the inner faces of the panes, (so the inner face of the outer pane and the inner face of the centre pane) and they control the emissivity at those surfaces, reflecting long wavelength IR inwards through the interstitial gap between the panes, but allowing long wavelength IR from outside to come in with only a slight reduction.

SMP (Silyl modified polymer) adhesive direct fix to profile which is direct fixed to external cladding. Non-polyurethane because it bonds to anything, no primer required, solvent and isocyanate-free. They do not release VOCs and other chemicals in the air that could have harmful effects. SIMSON ISR 70-08 AP high green strength (initial tack) to avoid or reduce clamping times. R1.3-2.0

Sika

Sikasil® SG-20 Structural sealant for use in structural sealant glazing systems

High-strength, 1-component silicone structural glazing adhesive, 1-component, neutral-curing structural glazing silicone adhesive, which combines mechanical strength with high elongation. It adheres to a wide range of substrates. Design tensile strength for dynamic loads: σdes = 0.17 MPa (25 psi) (ETA). DIN 6701 compliant.

DIN 6701-3 Verification: Actual load < Load limit of the bonded joint.

The bond classification is the first step in implementing DIN 6701. It ensures you have evaluated how much threat-to-life a bond will pose.

To do this, you can designate the bond into one of four categories.

- A1 – Bonds with high safety requirements. Failure of the bond will result in a threat to life or physical condition or will jeopardise the reliability of service.

- A2 – Bonds with average safety requirements. Failure of the bond may result in accidents that involve physical injury to persons. Or it may result in impairment of serviceability of the complete system.

- A3 – Bonds with low safety requirements. Failure of the bond results in loss of comfort at most. Accidents involving physical injury are unlikely.

- Z – Bonds with no safety requirements. Failure of the bond will not cause any threat to life or physical condition. It will not jeopardise the reliability of the service.

Dow

Dowsil 795 Silicone Building Sealant is a one component, neutral-cure architectural grade silicone for structural glazing and weatherproofing. Structural bonding of glass, metal and other materials. It is a medium-modulus structural sealant with excellent adhesion to a wide range of materials. DOWSIL™ 795 Structural Glazing Sealant has been tested and passed ASTM C1184 Structural Sealant Specification and it has ±50% movement capability in accordance with the ASTM C719 test. It is available in black, white, bronze and grey colours

- Tensile (7d/RT) > = 125 psi

- Elongation (7d/RT) > = 450 %

- Tear (7d/RT) > = 20 lb/inch

- The structural bite must be a minimum of 6 mm

- The glueline thickness must be a minimum of 6 mm

- Medium/High-modulus neutral-curing silicone sealant is more suitable for the SSG use.

Butyl Tape

HIGH-TECH BUTYL TAPE – (2MM X 12MM)

CODE: GTA-B2.12

The High-Tech, New Generation, Butyl Tapes are high performance glazing tapes that allow quick and waterproof glazing, when glazed correctly by a professional glazier. They form a watertight joint that prevents moisture intrusion.

- Suitable for single and double glazing applications

- Comes with a liner and core the same width as the tape, therefore applies just like foam glazing tapes

NOTE: Consult your timber joinery manufacturer / supplier for the suitability for use with their glazing details.

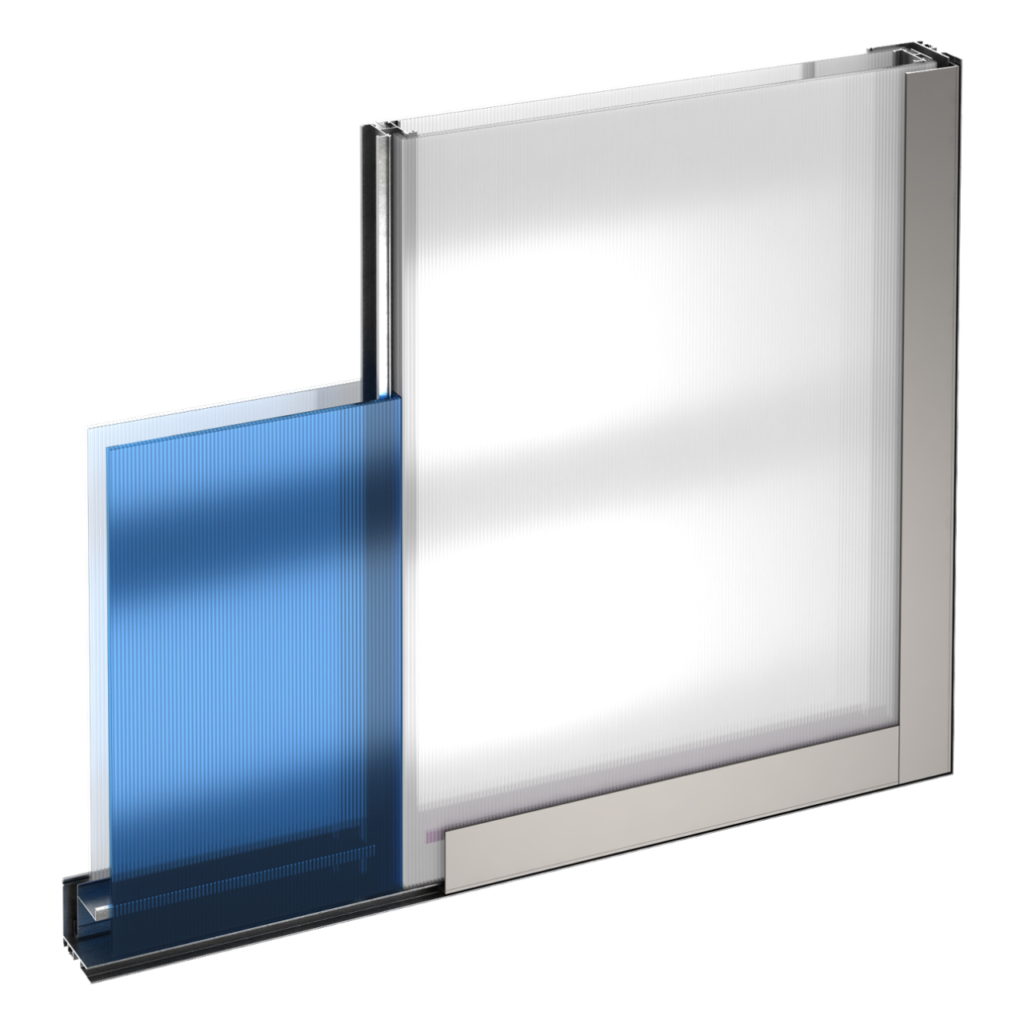

UniQuad® Window

TRANSLUCENT WALL & ROOF ASSEMBLIES

Energy-efficient UniQuad® Translucent Windows are versatile enough for new construction and renovation projects, and are a great solution for smaller openings. The unitized modular design is simple to install, and its concealed supports create a channel glass look but with less weight and lower cost. Systems may be customized with options including custom colors, graphics and LED backlighting, or enhanced with insulation for better thermal performance.

Product Highlights

- Removable Skin Technology (RST) allows removal of interior or exterior glazing panels without exposing interior spaces

- Internal Structural Support uses concealed aluminum support members for a continuous, flush look like channel glass

- Unitized, modular design enables fast easy installation and pre-assembly helps to maintain superior quality control

- System is warrantied to maintain translucence over time, letting in more light that can boost health and productivity

- Translucent glazing allows for unique backlighting opportunities

- Sustainability – aluminum and polycarbonate can be recycled and an Environmental Product Declaration is available

- System height up to 6 feet with limitless length (panelized in up to 12 foot sections)

- Technology Removable Skin Technology (RST) allows for the removal of the exterior panel while the interior panel remains in place

- Panel joint Structural member, mechanically interlocking

- Exterior skin 8 mm translucent polycarbonate panel with Nano-Cell® technology

- Interior skin 8 mm translucent polycarbonate panel with Nano-Cell® technology

- Color options: Standard – Clear Matte, White Matte, Ice White Matte

Consult Kingspan Light + Air for other color options and availability - Multi-color system: Option to select different colors for interior and exterior glazing panels

Certifications and Test Results

- ASTM D635, D1929, D2843, E84 per ESR-4745 – CC1

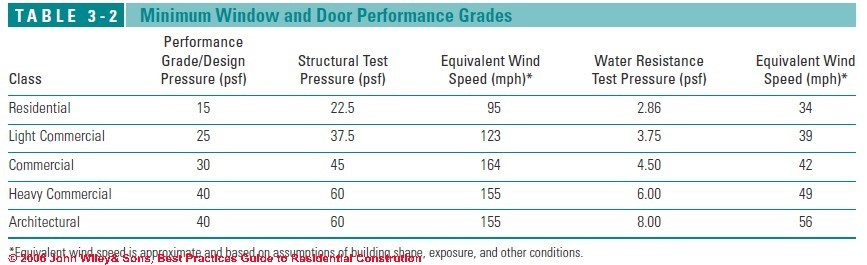

- Uniform Load Structrual / Spans – ASTM E330 Up to 40 psf at 6ft span

- Large Missile Impact / Cyclic Loading – Missile Impact Level D, Wind Zone 4, Cyclic Pressure – 40psf

- Water penetration – ASTM E331 Pass – 15 psf

- Air infiltration + exfiltration – ASTM E283 Pass – 0.30 cfm/ft2 at 6.24 psf

- Sound Transmission Loss (STC) – ASTM E90/E1332- 22-25

Thermal Performance

- U-factor: NFRC 100 – 0.21 to 0.32

- SHGC – NFRC 201 – 0.22 to 0.35*

- Visible Light Transmittance – NFRC 202 – 0.10 to 0.33*

Structural Bite Calculation for Windload

Minimum Structural Bite (mm) = Glass Short Span Dim. (mm) x Windload(kPa) x 0.5 / 138 kPa or 140 kPa

Glass Short Span Dimension (SSD) is the shorter of the two dimensions of the rectangular glass panel for example, on a 1.5 m by 2.5 m glass panel, the SSD is 1.5 m.

- Windload is the maximum wind pressure in Kilo Pascal (kPa) for a return period of 10 years based on local regulations. (Note: Some countries may have different rule or regulation for windload value, such as Australia is using 100 years weather data to determine windload). This value is provided by the design professional to Dow.

- 138kPa (or 140kPa depend on local building code) is the maximum allowable live load design stress used by Dow for our Silicone Structural Glazing sealants.

Structural Bite Calculation for Deadload

In unsupported Structural Sealant Glazing (SSG) designs, the deadload weight of the panel is supported by the structural silicone joint, see Figure 13. This situation commonly occurs when structural glazing is used on monolithic glass. Dow Silicone Structural Glazing sealants can support the weight of the glass provided stresses do not exceed the allowed design stress for deadload.

Provided the horizontal frame members are as rigid as the vertical members, Dow will consider both the vertical and horizontal or long edges of the frame in the deadload calculation. If the horizontal frame members will not support the glass under windload, only consider the vertical frame members in the calculation.

Structural Bite Calculation for Deadload

Minimum Bite (m) = 2,500 kg/m3 x 9.81 m/s2 x Glass Thickness (m) x Glass Cross Area (m2) / [2 x Height (m) + 2 x Width (m)] x Allowable Design Stress (Pa) for DL

- 2,500 kg/ m3 is the specific mass of float glass corresponding to approximately 25,000 N/m3 of specific weight.

- 9.81 m/s2 is a factor for gravity.

- The max allowable design stress for deadload for DOWSIL™ 983 Structural Glazing Sealant, DOWSIL™ 993N Structural Glazing Sealant, DOWSIL™ 795 Structural Glazing Sealant, and DOWSIL™ 995 Silicone Structural Sealant are 7,000 Pa.

- If the horizontal frame members will not be supporting the glass or will deflect under the deadload of the glass, just consider 2 x Height (m) in the denominator of the calculation.

For example, a 1.219 meter by 2.438 meter lite of monolithic glass at a weight of 14.8 kg/m2 will have a weight of 43.97 kg and a glass perimeter of 7.314 meters. Based on 7,000 Pa (or 703 kg/m2) deadload design strength, a bite of 9 mm is required.

International Structural Sealant Glazing Design Guidelines

Below are international standards or guideline that related to Structural Sealant Glazing design:

- ASTM C1401-14 Standard Guide for Structural Sealant Glazing

- ASTM C1249-06a (2010) Standard Guide for Secondary Seal for Sealed Insulating Glass Units for structural

- ETAG002 – 2005 Guideline For European Technical Approval For Structural Sealant Glazing Kits (SSGK)

- EN13022-1 Glass in Building – Structural Sealant Glazing – Part 1: Glass Products For Structural Sealant Glazing Systems for Supported and Unsupported monolithic and multiple glazing

- EN13022-2 Glass in Building – Structural Sealant Glazing – Part 2: Assembly rules

- EN15434 Glass in Building – Product Standard for Structural and/or ultra-violet resistant sealant (for use with structural sealant glazing and/or insulating glass units with exposed seals

- JGJ102-2013 Technical Code For Glass Curtain Wall Engineering

- Hong Kong Architectural Service Department General Specification For Building, 2012 version: Section 16 Curtain Wall & Section 20 Glazing

- ISO 28278-1: 2011 Glass in Building – Glass Products For Structural Sealant Glazing – Part 1: Supported and Unsupported monolithic and multiple glazing

- ISO 28278-2: 2010 Glass in Building – Glass Products For Structural Sealant Glazing – Part 2: Assembly Rules

- ASTM C1564-04 (Reapproved 2009) Standard Guide for Use of Silicone Sealants for Protective Glazing Systems

- ASTM C1392-00 (Reapproved 2014) Standard Guide for Evaluating Failure of Structural Sealant Glazing

- ASTM C1394-03 (Reapproved 2012) Standard Guide for In-situ Structural Silicone Glazing Evaluation

- ASTM C1487-02 (Reapproved 2012) Standard Guide for Remedying Structural Silicone Glazing

- ASTM C1564-04(2009) Standard Guide for Use of Silicone Sealants for Protective Glazing Systems

Carbon steel and galvanized steel are not appropriate surfaces for structural silicone glazing due to substrate durability concerns when exposed to corrosive agents. Painted steel is generally not acceptable for silicone structural glazing for the same reason. On an exception basis, steel components painted with high-performance industrial-grade coatings have been approved upon testing and review by Dow, the substrate manufacturer and the coating manufacturer

A flat surface with no gasket races, key slots, serrations or other irregularities is required.

Extruded mill finish aluminum is not an appropriate surface for structural silicone application due to poor adhesion.

The stainless steel must be of an architectural grade quality and should be submitted to Dow for adhesion and compatibility testing.

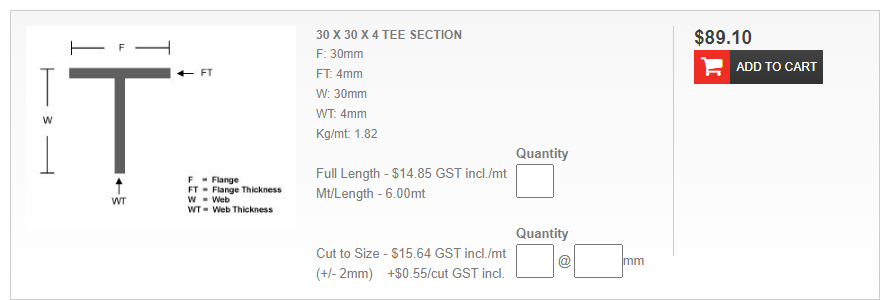

METRIC STAINLESS STEEL EQUAL TEE SECTION

Available in 6.000 Metre lengths in Grades T/304 and T/316.

20 X 20 X 3MM (0.88 KG/M) STAINLESS STEEL EQUAL T-SECTION

Grade 304 stainless steel is a commonly used austenitic stainless steel that is well-suited for a wide range of applications. It is highly resistant to corrosion, has good formability, and is easy to fabricate, making it an ideal choice for structural glazing frames in most indoor or protected outdoor environments.

Grade 316 stainless steel, also known as marine grade stainless steel, is a higher grade of stainless steel that provides excellent corrosion resistance, even in harsh marine environments. If the structural glazing frame will be exposed to harsh weather conditions, high levels of moisture, or frequent contact with salt water, grade 316 stainless steel may be a better option.

https://handysteel.com.au/miscellaneous-tee-section

T 35x35x3 1.62 35G kg/m 3mm web 2mm radius

Split-frame design:

Windows:

- Kitchen 2m wide x 1m high @ 1m above floor level

- Bathroom Laundry 1m x 1m high @ 1m above floor level

- Bedrooms 2m wide x 1m high @ 1m above floor level

- Lounge 2m wide x 2m high @ floor level

3M™ VHB™ Structural Glazing Tapes are durable, high performance two-sided acrylic foam tapes for the bonding of glass panels into curtain wall, commercial window and door systems and skylight/canopy systems.

ECHOtape’s Thermal Break Tape is designed for construction professionals who want to reduce thermal bridging on outer and inner framing in metal buildings. Used primarily in the installation of metal building panels and prefabricated wall panels, this tape is applied over the top of purlins or on girt flanges to act as a barrier or flash break between the outer shell and inner framing. This tape adheres strongly to both smooth and rough surfaces including corrugated metal. The paper release liner protects the adhesive from contaminants when the tape needs to be cut to specific lengths for use in tight spaces ensuring a strong bond once applied. FO-V2344/FO-V2348

Structural Silicone Glazing – Design & Modelling

glassonweb.com/article/structural-silicone-glazing-design-modelling

The structural bite for windload (live load) is calculated using the specified windload, glass or panel

dimension and sealant design strength of 20 psi (or 138 kPa).

4.1.4 Structural Bite Calculation for Windload

Minimum Structural Bite (mm) = Glass Short Span Dim. (mm) x Windload (kPa) x 0.5 / 138 kPa or 140 kPa

Glass Short Span Dimension (SSD) is the shorter of the two dimensions of the rectangular glass panel for example, on a

1.5 m by 2.5 m glass panel, the SSD is 1.5 m

63-6132-01-structural-sealant-glazing-manual-asia.pdf

3M VHB – Standard Roll Length – 32.9m, Standard Widths – 15, 20, 25, 30 mm

Note: For tape area calculations the following guidelines can be used.

Dynamic Loads:

For dynamic tensile or shear loads, such as wind loads, a design strength of 12 lb/in² (85 kPa) is used for 3M™ VHB™ Architectural Panel Tapes. This design strength guideline provides a safety factor of at least 5 and was established based on material property testing as well as ASTM dynamic load testing for curtain wall applications.

Static Loads:

For static tensile or shear loads, such as dead weight loads with no mechanical support, snow loads and other long-term loads, a design strength of 0.25 lb/in² (1.7 kPa) is used for 3M™ VHB™ Architectural Panel Tapes. This means 4 in² of tape per 1 lb load (60 cm² of tape per 1 kg load) should be used to support constant stress loads. This guideline provides a safety factor of at least 5.

Differential Movement:

3M™ VHB™ Architectural Panel Tapes can tolerate shear movement up to 3 times its original thickness (300% shear strain). This means 0.090 in (2.3 mm) thick tapes can tolerate shear strain up to 0.27 in (6.9 mm), 0.062 in (1.6 mm) thick tapes can tolerate shear strain up to 0.19 in (4.8 mm), and 0.045 in (1.1 mm) thick tapes can tolerate shear strain up to 0.14 in (3.3 mm).

Force/Stress Types:

In general, when designing with 3M™ VHB™ Architectural Panel Tapes, forces acting on the tape should consist of either shear or tensile type stress loads. This allows the stress or force to be applied over the entire tape area. Applications placing cleavage or peel type stress on the tape should be avoided as this will place the stress on the leading edge of the peel or cleaving.

Stainless Steel R value

Stainless Steel Stainless steel has a different metallurgical chemistry than carbon steel resulting in an R-value about three times that of carbon steel. Material costs for stainless steel are approximately four times that of A992 structural steel. However, with limited, strategic use of the material, additional costs can be minimized.

Documents/2012v03_thermal_bridging.pdf

Temperature Index 0.52

Beam Temperature at Example Design Conditions (-18°C Exterior & 21°C Interior) 2

Critical RH % at 21°C based on Beam Surface Temperature Conventional Construction C01-CC Uninterrupted steel beam 29%

Morrison_Hershfield_Report_Thermal_Break_Technology_for_Various_Construction_Types[6047].pdf

Certification Standards

The Gold Label certifies that a sample of a particular type of window passed performance tests for resistance to air leakage, water penetration, and wind pressure. In addition to unit testing, individual components of the window have passed independent performance tests making them eligible for use in AAMA-certified windows.

- Meet an air leakage standard of 0.30 cubic feet per minute or lower when wind speeds are at 25 mph. The lower the AL is the less air infiltration is allowed through the window.

- Windows must resist water infiltration up to 32 mph. Windows that allow water infiltration at speeds under 33 mph fail.

- Gold Label windows withstand at least 94 mph wind pressure. Structural strength is tested by measuring the amount of wind pressure the window can resist before it breaks.

To meet the New Zealand Building Code, windows and doors must be manufactured according to the New Zealand Standard NZS 4211:2022. All Window & Glass Association New Zealand members manufacture and test their units to the standards and performance required by NZS 4211:2022. Which is normally applied to prototypes of mass-produced windows before construction. It is concerned only with performance aspects of window systems and not the junction of windows to the cladding.

Tests such as AS/NZS 4284:2008 Testing of building facades focused on commercial cladding systems, and NZS 4211:2022 Specification for performance of windows focused on the performance of domestic-oriented windows.

With the introduction in 1992 of a performance-based Building Code, new methods to assess the weathertightness of windows and claddings were developed including E2/VM1 for low-rise construction and E2/VM2 for mid-rise construction.

E2/VM1 and E2/VM2 tests were developed from AS/NZS 4284:2008 and assess the management of drainage water. They require defects to be introduced through the cladding and expect any water from this to be managed. However, these defects do not always stress the window to wall junction and may also encourage designs with poor thermal performance. Our research partnership produced two evaluation methods:

- EM8 to assess the thermal performance of a window to wall joint (to be discussed in a future Build article).

- EM9 to provide a more robust assessment of the weathertightness of window to wall joints.

The northern part of the country, including Auckland, will have a two-step approach, with the R-value requirement lifting to R0.37 (from the current R0.26) on 2 November 2022, and then moving up to R0.46 from 2 November 2023. Other parts of the country will have to conform to the new code provisions (R0.46 or R0.50, depending on the region) by 2 November 2022.

EM9 assessment

EM9 assesses the weathertightness of the window to cladding interface and is intended to follow an E2/VM1 or E2/VM2 test. It is concerned with getting water out once it has got in. Preventing water ingress through cladding systems is not always possible so performance is determined by what happens to any water that does penetrate the cladding.

New Zealand does not have a test method for the weathertightness of direct-fixed claddings – these are reliant upon workmanship so testing may not be conclusive.

EM9 test introduces water

In E2/VM1 testing, drainage water must be directed out to the line of the cladding and is not allowed to drip in the cavity.

Within EM9, water is purposely introduced into the window installation system and is only allowed to contact durable non-absorbent materials of low permeability, resulting in a low risk of ongoing problems if the materials get wet.

Until IANZ accreditation to undertake this test at other labs can be obtained, this test will be available at BRANZ. Build-183-52-Feature-Weathertightness-Testing-Window-Weathertightness.pdf

Users of this Standard should consult with Ministry of Business, Innovation, and Employment – Building Systems Performance (BSP) to confirm their requirements.

Testing Methods

We use a range of methods to evaluate the weathertightness of roofs, wall claddings and other external openings such as windows, doors, meter boxes and pipes. Our testing capabilities include:

- measuring the water vapour resistance and hygroscopic properties of materials (to ASTM E96)

- computer modelling of moisture risk in structures

- assessing insulating glass units (IGUs)

- testing of assemblies under the combined action of water and wind pressure

- field monitoring and diagnosis using environmental sensors, blower door pressurisation techniques and tracer gas methods.

Standards we test to

BRANZ can test to a range of standards. Many are accredited by International Accreditation New Zealand (IANZ).

Windows and Doors

We are accredited by IANZ to test windows and doors to the following standards:

Sash torsional tests in accordance with NZS 4211:2008 Specification for performance of windows

The test requirements defined in NZS 4211:2008 and AS 2047:2014 Windows and external glazed doors in buildings in accordance with the test methods of AS 4420.0:1996 Windows – Methods of test – General introduction and list of methods:

- Deflection test

- Operating force test

- Air infiltration test

- Water penetration resistance test

- Ultimate strength test.

We test to the following standards for windows, doors, wall claddings, floor and ceiling panels in accordance with AS/NZS 4284:2008 Testing of building facades:

- Structural test at serviceability limit state air infiltration test

- Water penetration by static pressure (and as modified by E2/VM2 (7/04)) test

- Water penetration by cyclic pressure (and as modified by E2/VM2 (7/04)) test

- Wall claddings to E2/VM2 Cladding systems for buildings up to 25 m in height – including junctions with windows, door and other penetrations

About IANZ Endorsements

IANZ-endorsed test reports are recognised by regulators in countries where accreditation authorities are signatories to the International Laboratory Accreditation Cooperation (ILAC) or Asia-Pacific Accreditation Cooperation (APAC) Mutual Recognition Arrangements. They are equivalent to test reports endorsed by the National Association of Testing Authorities (NATA) Australia.

Verification Method E2/VM2: Cladding systems for buildings up to 25 m in height – including junctions with windows, door and other penetrations. Specific wind pressure up to a maximum ultimate limit state (ULS) of 2500 Pa (0.36psi 200km/h). Download

BRANZ testing estimate:

“We can test units if up to 2400 x 2400 mm in Wellington, or 4200 x 4200 in Auckland.

NZS4211 and AS/NZS 4284 are similar tests which can sometimes be interleaved, although if one test damages the sample, then we will need a second test sample.

NZS4211 including the torsional test typically costs $12,000 plus installation, but the 4284 test can cost more if it includes seismic testing. Sometimes the tests are able to be interleaved with two reports.

We should talk. What’s your phone number?

John Burgess”

ETAG002 and ASTM C 1401 are the main international Standards providing regulations for design of silicone joints in Structural Sealant Glazing (SSG) applications.

They provide calculation methods with reference to flat glass units with regular shape, in vertical position, bonded along all sides to load-bearing profiles, experiencing limited deflections and subject to wind load, dead load and temperature variations. glassmachine.com/calculation-method-for-structural-sealant-glazing-joints

Such Standards provide effective rules for typical façade systems consisting of vertical glass units with rectangular shape, bonded along all sides, mechanically supported or unsupported, experiencing limited deflections and subject to wind load, dead load and thermal variations.

The calculation method proposed herein is currently under discussion within CEN/ TC349/WG2 for upgrade of current Standard procedures.

The strength offered by a silicone joint depends on the duration of the load applied. For this reason, ETAG002 [1] identifies the following adhesive strengths:

The dynamic tensile strength σdyn, defined as σdyn = RUT,5 / γtot where:

RUT,5 is the characteristic ultimate tensile strength of the adhesive γtot = 6 is the total safety factor RUT,5 value is obtained from tests performed on H-specimens with joint dimensions 12mm x 12mm x 50 mm (Fig.1), tested in tension at the speed of 5 mm/min.

This strength is used to determine the bite dimension of the SSG joints loaded by wind.

The dynamic shear strength τdyn, defined as τdyn = RUS,5 / γtot where: RUS,5 is the characteristic ultimate shear strength of the adhesive γtot = 6 is the total safety factor RUS,5 value is obtained from tests performed on H-specimens with joint dimensions 12mm x 12mm x 50 mm, tested in shear at the speed of 5 mm/min.

This strength is used to determine the thickness of the SSG joints due to thermal dilatations.

The static shear strength τstat, defined as τstat = τdyn / γc where: γc ≥ 10 is a creep factor

Additionally, the creep test described in Section 5.1.4.6.8 of ETAG002 [1] is used to control that the static shear strength adopted ensures the elastic behavior of the joint after being stressed under permanent shear and simultaneous dynamic tensile loads, while limiting creeping phenomena.

In unsupported systems, the static shear strength is used to determine the bite dimension of the SSG joints loaded by the glass weight.

Typical durations considered in façade design are:

- t ≤ 5 sec – wind load

- t ≤ 1 min – barrier load

- t ≤ 1 day – maintenance load, climatic load

- 1 week ≤ t ≤ 4 weeks – snow load

- t ≥ 90 days – dead load, cold bending load

When the load duration is very short and impulsive, usually the deformation speed of the joint become more relevant:

- m/s ≤ s < 6.0 m/s – blast load.

Dow must review and approve all Structural Sealant Glazing (SSG) joint dimensioning. All exceptions must be handled on a project-specific basis and documented in writing by the Dow Technical Service Representative.

- The structural bite must be a minimum of 6 mm.

- The glueline thickness must be a minimum of 6 mm.

The structural bite for windload (live load) is calculated using the specified windload, glass or panel dimension and sealant design strength of 20 psi (or 138 kPa).

Structural Bite Calculation for Windload

Minimum Structural Bite (mm) = Glass Short Span Dimension (SSD) is the shorter of the two dimensions of the rectangular glass panel for example, on a 1.5 m by 2.5 m glass panel, the SSD is 1.5 m.

• Windload is the maximum wind pressure in Kilo Pascal (kPa) for a return period of 10 years based on local regulations. (Note: Some countries may have different rule or regulation for windload value, such as Australia is using 100 years weather data to determine windload). This value is provided by the design professional to Dow.

• 138kPa (or 140kPa depend on local building code) is the maximum allowable live load design stress used by Dow for our Silicone Structural Glazing sealants.

Window Sand Curtains

Make your own:

Window Shutters

100mm EPS encased in ply (Potential condensation, so no MDF). PVA/Aliphatic glue.

Draught stop seals. Not really critical as the loss isn’t big enough when 99% of the glass is covered.

170 Degree Hinges Frameless Cabinet Door Hinges

This mechanism to fold up against wall. Bifold with lift-off hinges.

Fold back flat mechanism:

Well-fitted shutters can improve the energy efficiency of your windows by as much as 50%

Woven Bamboo Ply LV Sheet size: 2440x1220mm, 1mm Approx $100/sheet (3mm MDF is $17)

Woven Bamboo Ply Sheet size: 2440x1220mm, 1mm